What can ERP do for managers running a small shop? The answer is pretty much everything, if you’re aiming to boost sales, make manufacturing production goals and build high-quality parts, and in turn satisfy customers and make a decent profit.

While enterprise resource planning (ERP) is often seen as the domain of large-scale manufacturers, job shops of all sizes in discrete manufacturing greatly benefit from digitizing operations with modern software that often lifts the smaller builder out of working off paper-based systems and Excel spreadsheets into the latest ERP automation with digital scheduling and production analysis tools.

The latest ERP software can be tailored to use at smaller shops, with easy-to-use smartphone interfaces for accessing shop ERP data and new big-board electronic schedulers offering easy touch-screen input on the factory floor. Many options are available now to small manufacturers, including either on-premises installations or newer cloud-based ERP systems that promise to dramatically cut technology costs by removing most of, or even eliminating, the costs of maintaining an expensive IT infrastructure.

Tailored for Small Shops

Not all ERP systems are built alike, and small shops with well under 100 employees might be best suited to shop-floor management and ERP systems that are custom-built for the smaller operator. A full-fledged ERP system from the big names in the business, say from SAP, Oracle or one of the many enterprise-level applications, may not be ideal for many smaller shops.

“Feature-wise and functionality-wise, we have capabilities that are found in the larger systems,” noted Henning Industrial Software (Hudson, OH) President Rich Henning. “The depth and breadth of what we cover is large,” but without the big price tag of large ERP systems, said Henning, developer of Visual EstiTrack ERP software. For smaller manufacturers, the investment in large enterprise-level ERP systems can strain their finances. “Even Microsoft Dynamics is pretty expensive for a small shop,” said Henning, noting that shops can spend thousands of dollars just on the integrators installing such systems. “They can be overkill.

“Robust ERP and shop-management software systems are fully integrated operational and financial management systems that are designed help SME [small-to-medium enterprise] manufacturers manage nearly all aspects of their businesses,” Henning said. “Well-designed systems will support just about every functional area of a manufacturing facility. This includes managing the entire product lifecycle starting with Customer/Prospect Management, CRM, Job Estimating, Engineering, Sales Orders, Shop Orders, Scheduling, Capacity Planning, Material Requirements Planning, Purchasing, Receiving, Job Labor Reporting, Quality Management [i.e., Non-Conformance, Corrective Actions, etc.] and finally a fully integrated Accounting system [A/R, A/P, Fixed Assets, GL, Payroll and Human Resources Management].”

By methodically managing via a fully integrated ERP system every functional area of a manufacturing facility, small manufacturers can gain operational efficiencies and improve quality by gaining a true insight on their operations that only a well-designed fully integrated ERP system can provide, he added. “It can help a manufacturer turn all their day-to-day transactional data into actionable business intelligence,” Henning said, “that can lead them to higher levels of productivity and efficiency.”

Small shops need an ERP system to effectively run today’s manufacturing operations, which are more complex and fast-paced than ever, especially in made-to-order manufacturing environments.

“The truth is, in today’s business landscape, no business is too small for an ERP solution,” said Jeremy Klosowski, GM and director, sales and marketing, Realtrac Performance ERP (Livonia, MI), developer of Realtrac ERP. “Realtrac allows small businesses to operate, appear and compete like a large-scale enterprise. It allows management to do much more with much less and capture cost with true visibility while sharing information across various departments in an organization to reach production goals.”

Check the Big Board

Newer technologies like big-screen options take ERP scheduling and job management from paper or the desktop to very large touchscreen-enabled electronic boards accessible in the shop and on the factory floor. In the past year, Henning, who worked with a longtime customer, Littlestar Plastics (Rockford, IL), to develop a convenient shop-floor big-board touchscreen, introduced its new Touch Scheduling Board. Similarly, Realtrac this fall introduced its new Rightboard touchscreen scheduling system.

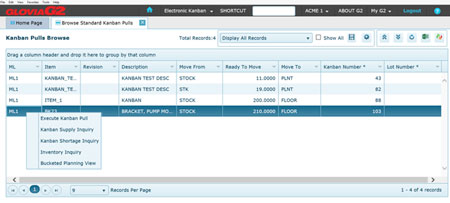

More mobile information is easily accessible by users via either smartphones or tablet computers with the new GLOVIA G2 ERP system from CrescentOne Inc.

“Our Touch Scheduling Board emulates and is designed to replace the magnetic scheduling boards often found in shops,” Henning said. “Our touch-based scheduling board provides an intuitive user interface and familiar magnetic board metaphor, thus reducing the user’s learning curve, making it much easier for shop-floor personnel to prioritize operations, view/set statuses and move operations from one work center to another.” The scheduling board also enables authorized users to change run quantities based on release coverage, view due dates, redefine routers and assign employees to work centers and/or operations.

Users can even color code cards by customer, define on-the-fly operational performance notes that can be shared with other shop personnel and set a variety of shop order statuses, such as “Waiting for Material,” Henning added, and animated icons are used to show hot and late jobs.

Realtrac is always making improvements to stay competitive and be the first in its class of small-to-medium size shops, Klosowski said. “We have recently launched our touch-screen electronic Rightboard, and RFQ [Request for Quote], to name a few. Each feature has an extremely large impact for costing and real-time operations,” Klosowski noted. “The Rightboard allows you to move jobs throughout your departments to workstations from a job pool with drag-and-drop technology, dramatically increasing workflow. The touchscreen allows you to see where your operations are in your shop as well as the timeline for that operation capturing employee rates. RFQ has multiple levels of quoting and adding vendors, shaving hours off your week.”

Mobile Access to ERP

The use of mobile devices with smartphones and tablets also continues to grow, and mobile devices have become much more accepted on the shop floor. “Henning Software offers a mobile option that we have named iVET that has an employee portal feature enabling shop-floor personnel to view their operational performance statistics, efficiencies, workcenter schedules, inventory levels, job assignments and to clock in/out of jobs using their mobile device, freeing them from having to walk up to a tethered computer, thus improving shop-floor efficiency,” he said.

Newer technologies aimed at making ERP easier to use include software employing .NET and SQL (structured query language), as well as HTML 5, which enables running it on laptops and on mobile devices, noted James Gorham, Executive Vice President of CrescentOne Inc. (El Segundo, CA), developer of the GLOVIA G2 ERP software.

“The risk is way higher for a small company,” noted Gorham of small shops seeking ERP solutions. “If they get it wrong, they can go out of business. Their ability to recover is obviously more fragile.”

ERP systems give small shops key controls for critical items including Bill of Materials (BOM), he noted, and it also gives the smaller operator effective cost controls. “The quicker they can adopt ERP the better,” Gorham said.

Going to the Cloud

For a lot of manufacturers, a key decision with ERP systems remains whether to go with the more traditional, tried-and-true on-premises installations—software that is licensed and installed locally—or to go with either a cloud-based system or one that is a hybrid, a combination of those two options. There are pros and cons to each approach.

“In the face of growing competition and a challenging business climate, many job shops and manufacturers are looking for ways to reduce costs, streamline operations, and improve the bottom line. Implementing ERP software is a proven solution for running a business efficiently and effectively,” said Kathie Poindexter, senior manager, product marketing, Epicor Software Corp. (Austin, TX). “Yet a large percentage of manufacturers have held back from implementing an ERP system due to high initial costs, long implementation times, and competing demands for time and resources.

“However, today ERP is being made more accessible to small shops [via reduced cost of ownership and complexity] so they too can streamline business processes and break down barriers to growth, while remaining agile for rapid response to customer demands and evolving markets,” she added.

ERP allows small manufacturers to track, measure, and monitor their entire business, from shop floor to top floor and from raw materials to final product, Poindexter said. ERP also boosts efficiency with real-time, actionable visibility into plant and business operations; reduces costs and streamlines processes; optimizes lean manufacturing to focus on the key priorities to make smarter decisions, eliminate waste and increase customer satisfaction; and allows adapting to new manufacturing methods, changing customer requirements, and evolving business strategies, she said.

“This is all done via a single platform for better real-time collaboration. Since many small shops have limited IT resources to manage/deploy software, many are opting for a hosted cloud ERP solution, which is delivered in a manner that minimizes complexity,” Poindexter added. “This also has cash-flow advantages, allowing businesses to pay as they go from OPEX [operating expenses] budgets vs. CAPEX [capital expenses].

“Cloud ERP is perfect for small manufacturers as it ideally facilitates the collaborative nature of manufacturing across the entire supply chain,” Poindexter said. “Thanks to cloud deployment models, which reduce the infrastructure and IT support requirements related to hosting and management of software, small manufacturers can now access ERP capabilities that were previously out of reach. Those shops are in a prime position to get the most out of the cloud, as their size necessitates a large, agile computing solution while their IT budgets generally prohibit a robust, in-house data center.”

Small shops can benefit greatly from cloud-based systems, said Realtrac’s Klosowski. “I believe that the cloud-based system has the potential to be a major tool for smaller shops,” said Klosowski. “It provides a cost-effective environment that backs up all the information while providing complete shop-floor control as being a sole manager for a smaller group of individuals.

“In addition to being cost-effective, Realtrac’s cloud-based ERP allows you to grow your business while managing operations from a distance,” he added. “There have been extreme advancements in ERP. Having a cloud-based solution allows the user real-time visibility. As anyone in this industry knows, manufacturing changes almost at the same speed as technology, inventory changes, demand changes, and equipment changes. With this visibility it allows the manufacturer to provide the right quantity and time and adjust to scheduling changes at the right time.”

The major plus for cloud ERP is users don’t have the IT infrastructure and related costs, added CrescentOne’s Gorham. “It’s basically outsourced. The updating of the system on the cloud, all of that is taken care of,” Gorham said. “The downside is you don’t own the solution. It’s a run-to-apply solution.

“We have some customers that start in the cloud and then port to the on-premises solution. That’s an hour or so of work at most, and the reason I can say that is it’s exactly the same solution. Most of our competition, they’re actually two solutions. Or they’re the same, but they cut it down to make it perform in the cloud. Our software is architected to be sub-second response times. That takes away the barrier if you want to move to the cloud, or the other way around.”

Cloud Concerns Linger

Many manufacturers still are hesitant to adopt cloud ERP, for varying reasons. “We do see some smaller businesses that are looking for cloud solutions, but a large number of them are still most comfortable with a software package that installs on-premises,” said Dan Griffin, director of product management for Macola (Dublin, OH), an ERP software provider and a division of Exact, which is based in the Netherlands. “Smaller businesses, those without a large IT staff, have concerns around cloud, specifically as it pertains to security, access and data ownership. Furthermore, cloud software often has limited configuration options—leaving a small business in a position to have to change its processes to work around the software.”

Griffin said Macola also sees that smaller businesses are concerned with the lifetime cost for purchasing software in the cloud. “The cost of entry may be lower, but the total cost of ownership can outpace a traditional software purchase in a few years.”

Typically, small businesses that select a “pure cloud” solution are doing so because of the lower barrier to entry, Griffin said. “Some of the benefits associated with pure cloud—such as 24/7 accessibility—are also available with traditional ‘on-prem’ software,” Griffin added. “For example, even with software on-premises, Macola 10 can be accessed via Web browsers, tablets and mobile devices. We also have customers who choose to create a ‘private cloud’ by hosting Macola with a provider like Amazon Web Services to gain benefits around hardware and infrastructure management while still maintaining ownership of their software deployment.”

In more rural areas, like much of the territory covered by Henning in the Midwest, worries over Internet broadband availability remain a key issue for manufacturers thinking of running shop operations on the cloud.

“That’s a real concern,” Henning said. A company can run its entire infrastructure on the cloud, but the broadband connection cannot fail, as it did recently in the area where Henning is based, when a trunk line interrupted the VOIP (Voice Over Internet Protocol) broadband connection that Henning’s own business uses. “We were down for like 36 hours. If somebody has that happen, that’s a real concern,” Henning said. “The risk is high.”

A lot of people are doing more of a hybrid approach, he added. Software-as-a-Service (SaaS), is the true leasing approach, said Henning. But there are other options available to users who do not want to use a true cloud ERP, such as using a Windows server running in the cloud. “There’s no magic to this cloud stuff really,” he said.

“From our customer experience, we have not seen a great demand for cloud-based ERP systems up to this point,” Henning stated. “Most of our customers still feel more comfortable with an on-premises approach because that offers them more control over their systems and data. The fact of the matter is that companies wanting to use an off-premises-based ERP system must have the availability of very fast and reliable high-speed broadband Internet services, and broadband Internet services are not always available or as reliable in more rural areas of country where many smaller manufacturers may be located.”

Henning said some customers have chosen to move their computer infrastructure into the cloud by both using a cloud-based server as well as cloud-based workstations connecting remotely via thin-client remote desktop connections. If broadband is available, there can be a potential cost savings by using virtual servers and workstations in the cloud, he added.

“By running their computer infrastructure in the cloud, companies can avoid the capital expense of buying their own servers and workstations by using simple thin-client devices. By avoiding the cost of managing their own computer infrastructure, there may be some opportunity for cost savings.”

This article was first published in the December 2016 edition of Manufacturing Engineering magazine. Read “ERP Software for Small Shops” as a PDF.

Advanced Manufacturing Media – SME

U.S. Office | One SME Drive, Dearborn, MI 48128 | Customer Care: 800.733.4763 | 313.425.3000 | sme.org

Canadian Office | 7100 Woodbine Avenue, Suite 312, Markham, ON, L3R 5J2 | 888.322.7333

Tooling U-SME | 3615 Superior Avenue East, Building 44, 5th Floor, Cleveland, OH 44114 | 866.706.8665 | toolingu.com

© Copyright 2016 SME · All Rights Reserved

With the name Fujitsu behind this product, GLOVIA G2 offers the best ERP solution for discrete manufacturers worldwide.

Click Here to Download the Report!

Click Here to Download the Report!