Who:

With subsidiaries throughout the world, TRB – a fully owned subsidiary of Tokai Rika Japan – was established in the UK in 1998, and supplies components to Toyota, Saab, Volvo, Ford, General Motors and Chrysler. The group employs 10,000 people and has an annual turnover of approximately $1.7 billion.

Website:

Location:

St. Asaph in Wales

Business Problem:

In order to keep precision and mass production at its height, TRB was looking for a solution that incorporated Kanban.

Solution:

CrescentOne’s seamless integration of the Kanban system in their ERP solution proved to be the deciding factor to ensure streamlined production and delivery processes for TRB.

Benefit:

By implementing the glovia.com Kanban system, TRB reduced the company’s overhead and increased its profit margin.

Whether the end product is made to order or mass produced, an efficient supply chain is a prerequisite for successful manufacturing. In the automobile industry, which has one of the world’s most complex supply chains, it represents life or death. This is an industry where precision and mass production go hand-in-hand, and where customization of the end product creates innumerable permutations of the finished article.

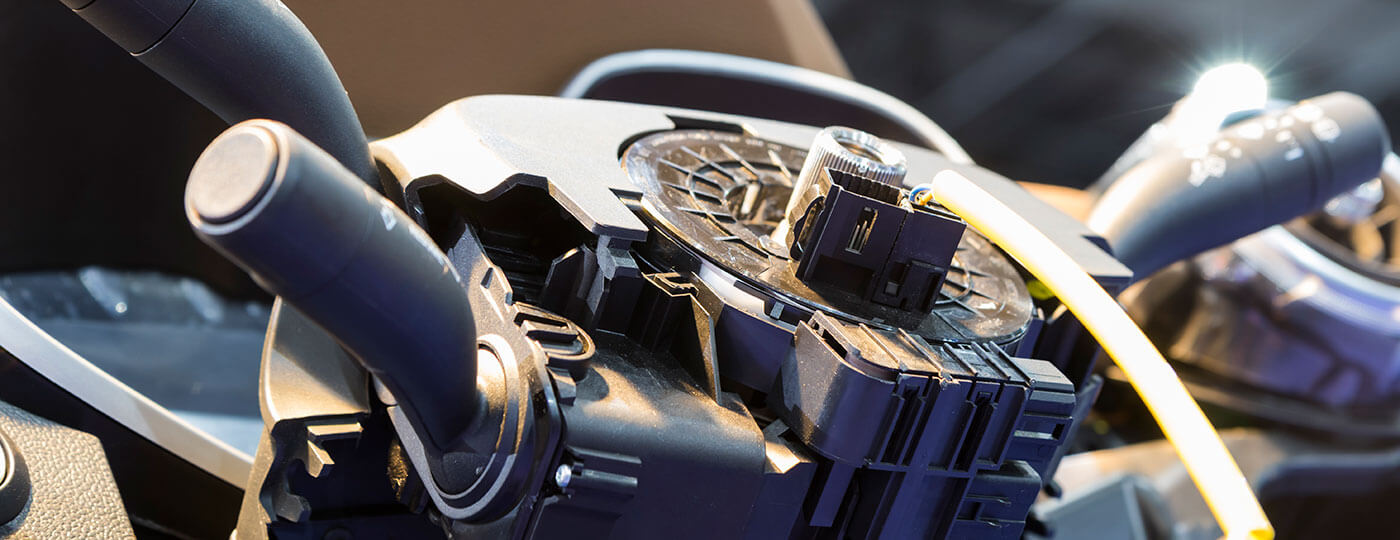

To keep the production lines rolling, and supplied with the right components at the right time, the car makers rely on companies like TRB, which makes everything from steering and airbag systems to switches and key cylinders.

TRB – a fully owned subsidiary of Tokai Rika Japan – was established in the UK in 1998 at a green field site near St. Asaph in Wales. The parent company, which has subsidiaries throughout the world, supplies components to Toyota, Saab, Volvo, Ford, General Motors and Chrysler. The group employs 10,000 people and has an annual turnover of approximately $1.7 billion.

Kanban Integration

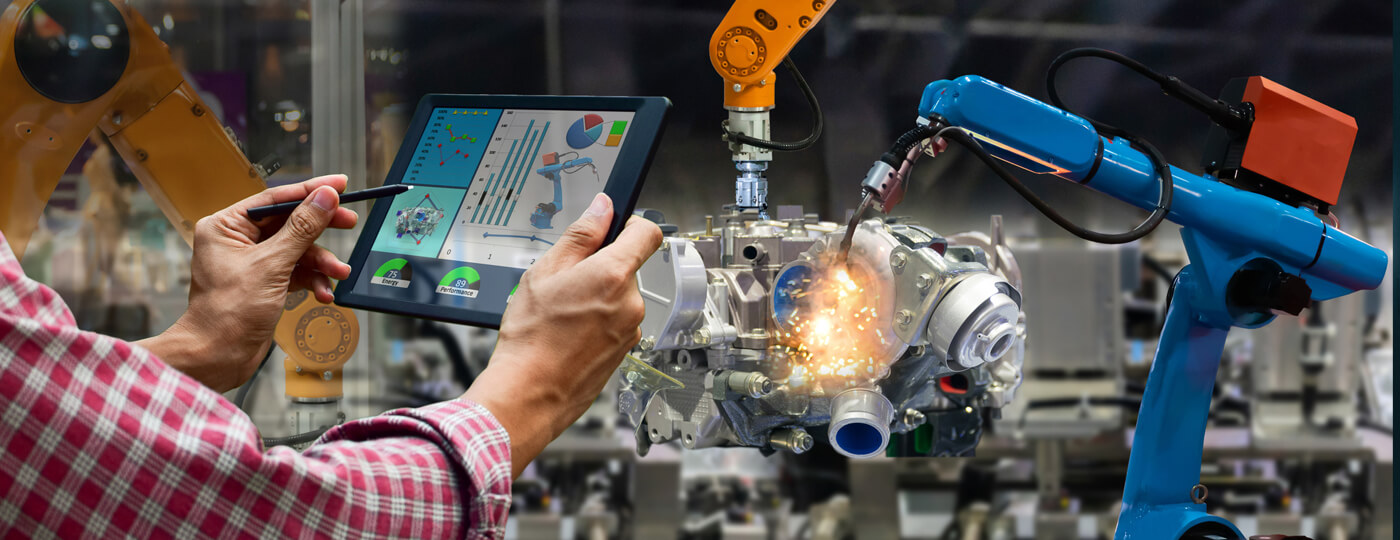

For its main production system, TRB uses the Kanban application to simplify inter-working. “We’ve customized Kanban and the interface with the CrescentOne system,” says TRB’s production engineering manager, Norihko Yamaguchi. “Kanban is used for the front-end. It provides graphic displays and enables us to control the production line. And it passes information to CrescentOne, so the two systems are tightly integrated.”

Integration with Kanban was a key requirement for TRB, and it was one of the deciding factors in their choice of CrescentOne. “The entire package is very comprehensive compared with other systems,” says Yamaguchi, “and the product is competitively priced. More importantly, CrescentOne has production controls like MPS and MRP. You can customize it easily, and it integrates well with financial systems. So our production and financial management are very tightly coupled.”

TRB is the first of the Tokai Rika Japan subsidiaries to have implemented CrescentOne, and Yamaguchi believes it is more cost effective than solutions such as Baan, SAP and BPICS, used elsewhere in the group.

“With other software systems you have to develop a lot of modules yourself, whereas CrescentOne is an out-of-the-box solution. All the modules are already integrated and it is just a matter of mapping our business plan to those modules. The parent company is very interested in the UK implementation and it could set the pattern for other plants around the world.”

Speed and Accuracy

TRB uses CrescentOne primarily for production planning. Orders arrive via EDI and Kanban calculates how many parts have to be made. The CrescentOne MPS module manages the production cycle; other modules handle stock control and cost calculation. In fact TRB employs most of the CrescentOne modules across its various production and delivery processes.

For materials manager, Craig Smith, the major challenge is timing. “Speed is of the essence because our customers talk in terms of hours. That means we plan production down to one day’s stock of finished goods, and they may well collect several times in one day.” CrescentOne plays a key role in achieving the necessary response times.

“We import live information from the production shop every hour, so we can tell what’s been made and if we’re on target for the following day’s pickup. It’s as tight as that.’

e-Commerce

Electronic data interchange (EDI) with firms such as Toyota, drives the production process. TRB receives both firm orders and regular forecasts of requirements electronically. These form the basis for TRB’s suppliers’ schedules. The EDI system also generates picking lists for the materials required the following day. “All the processes are linked,” says Smith, “and we try to eliminate manual intervention so that data is input only once. CrescentOne has helped us to automate the process and feed the EDI information into the production system.”

“One facility that has proved to be very effective is the Advance Shipping Notice, sent by EDI, which informs us of incoming shipments. We want to build on that so that people have more time to check the goods rather than sitting in front of a computer entering up receipts and delivery dates.”

The biggest issue for us is cost. Possibly the most important thing that CrescentOne has done for us is to reduce our overheads and increase profit margins.

Management Information

TRB also has a Web site which duplicates the EDI information and generates the delivery paperwork that accompanies the finished goods. TRB wants to make more extensive use of the Internet and it is currently looking at the various options within CrescentOne for handling blanket orders.

The objective is to streamline the whole ordering business, cut out the paperwork and reduce the cost of raising orders.

But there are limits to how far you can go in eliminating paper work. Data coordinator, Sarah Nicholls, for example, is responsible for providing reports to Yamaguchi and the management team. She’s also one of two TRB staff accredited to use CrescentOne’s Clear Express Internet site, which provides direct access to CrescentOne’s European Service Center.

“I can get instant real-time information from the production line and the accuracy of the CrescentOne data is excellent,” she says. We can produce ad hoc reports in minutes and so far we’ve been able to meet everyone’s demands.”

Service and Support

“As far as Clear Express is concerned, we can look at any logged issues that have been raised, check progress and even close off issues straight away. It avoids lengthy telephone calls and e-mails.

“I have to say that the support we get from CrescentOne is very good. We can direct any issues through the European Service Center.

“They either respond directly or refer the problem to a consultant – and we get immediate attention!”

Customer Relationships

At present, TRB is an assembly-only operation, sourcing many of its components through the parent company in Japan. “Our customers see us as a quality company,” says sales manager, Steve Parrish. “This manifests itself not just in our products but in our responsiveness and our commitment. My staff are using CrescentOne and we’re already finding quicker ways of doing such things as sales forecasting. Once people are fully trained on the system, I think they will get better at using it. And that means we’ll be able to answer customer queries even faster. It’s bound to help our customer relationships.”

Reducing Costs

At some stage Parrish expects TRB to start full scale manufacturing in-house to reduce costs, and that will trigger a major expansion. Even with the existing assembly-only operation, he expects turnover to triple by 2003.

“You have to remember that we work in a very competitive field,” adds Norihko Yamaguchi, “and the biggest issue for us is cost. Possibly the most important thing that CrescentOne has done for us is to reduce our overheads and increase profit margins.”