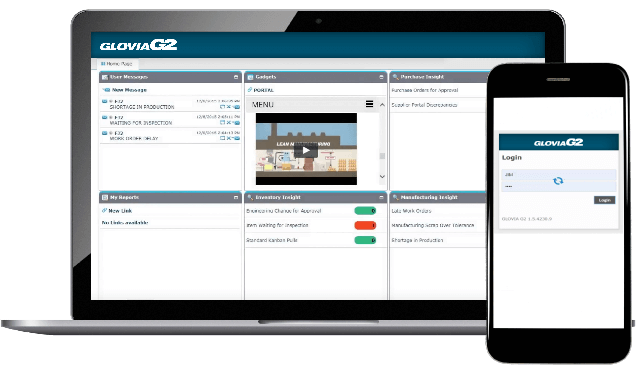

Benefits of Asset Lifecycle Management

By proactively planning maintenance activities, by monitoring expenditure on all assets and by seeing the overall workload for maintenance technicians, a company can improve manufacturing efficiency while driving down MRO costs.

Asset Definition

In GLOVIA G2’s Asset Lifecycle Management ERP module, assets are defined, categorized and described in the Asset Management workbench. An asset may contain multiple modules, each with their own maintenance schedule, and may have specific components identified that are defined down to the serial level. All service plans, maintenance costs and the current state of an asset can be seen at a glance in the workbench. There is unlimited text capability, and, any number of documents, manuals, drawings, diagrams etc. can be attached to an asset. The location of an asset can be identified, and, if appropriate, the asset can be linked to a GLOVIA G2 production machine. This linkage enables automatic update of counters so that maintenance schedules can be determined based on production volumes. Where this data is not available from manufacturing, simple screens allow users to quickly enter counter information directly from the asset.

Maintenance Definition

For all planned maintenance, the Asset Lifecycle Management ERP module makes it possible to define:

- The resources and amount of time typically required to perform the service,

- The materials that are likely to be consumed during the service (filter, oil, parts, etc), and,

- Any specialist tools or equipment needed to perform the service.

This information provides a baseline, against which the actual time and materials expended can be compared.

Maintenance schedules can be defined based on production volume counters, date intervals, or other flexible formats. For example, service could be scheduled for the last working day of every month or every 10,000 units produced. Service plans can be used to define a fixed planned schedule of maintenance activity or a flexible maintenance schedule where the next planned service is determined based on a pre-defined interval after the last service is actually completed.

Unplanned Maintenance

Regardless of how well maintenance is planned, a significant amount of unscheduled maintenance activity may be required and will result in the consumption of resources. This unplanned maintenance activity may be the result of breakdowns of production machines, or, it may simply be activities that, by their nature, cannot be planned. A microwave not working in a break room or a light not working in the board room are just a couple of examples of maintenance issues that cannot be planned for.

Using a simple to use Request for Maintenance workbench, a user can submit maintenance requests of any type and track progress through the maintenance/repair process, without having to be experts in either managing or maintaining the asset.

The process is designed to make it simple to log and manage maintenance requests from the very generic ‘lights are flickering in my office’ to the Pacific‘s oil leak on the hydraulics module of asset 124’.

Once a maintenance request is entered, email notifications can be sent and the request is immediately visible in a maintenance supervisor’s workbench.

Maintenance Planning

All maintenance requirements, whether planned or unplanned, are visible in the maintenance planner’s and/or supervisor’s workbench. From there, the maintenance requests can rejected, updated or converted to maintenance orders, assigned priorities and assigned to teams or maintenance engineers with the necessary skills and availability. Where activity needs to be conducted before the maintenance activity can begin, a supervisor can raise a maintenance order, but hold it pending completion of the necessary pre-repair activity. For example – perhaps an investigation needs to be carried out regarding why the failure occurred, or, the procurement of required materials is necessary prior to commencing any repairs.

Maintenance Execution

GLOVIA G2’s Asset Lifecycle Management ERP module enables maintenance resources to see all work that has been assigned to them listed in their own personal workbenches. They are able to view the details of the open maintenance orders and accept them. They can also see all unassigned maintenance orders accept those that they intend to work on. Once accepted, they can perform the tasks assigned.

For example:

- A shop packet can be printed identifying the maintenance tasks required, materials needed, etc.

- Materials issued from MRO stores can be booked,

- Labor/machine time can be booked to the order,

- Etc, etc.

During the performance of a service, whether planned or unplanned, any of the details and serial information worth recording can be recorded. This creates a history of not just the overall asset but the replacement history of key components.

Disparate systems, duplication of effort and custom interfaces are avoided by leveraging the existing fully integrated extensive features of the GLOVIA G2 manufacturing ERP application suite, including Inventory Control, Electronic Kanban, Purchase Orders, Vouchering, Payments, General Ledger, Fixed Assets, etc.

Summary

The Asset Lifecycle Management module is fully integrated to the extensive ERP application suite. It provides sophisticated, but simple to use, workbenches and application capabilities to identify, plan and manage maintenance requests from start to

finish and to record the maintenance activities carried out and any changes/updates made to assets.

Asset inquiries and reports show planned and actual expenditure on every asset over time, with historical details of component replacements for detailed analysis.

CrescentOne’s Asset Lifecycle Management will add value to your company by enabling you to get your assets under control and become more efficient.

Download CrescentOne data sheet to learn more about implementing our GLOVIA G2 Asset Lifecycle Management ERP Module at your company.

DownloadExplore More Capabilities

Select a product category below to see how CrescentOne can improve a particular aspect of your business