Improved Cost Management

As product designs change, operational processes improve, service needs change and new suppliers are found, you must be able to determine the cost impacts quickly and accurately. You need to know what actions should be taken to correct problems and when to adjust prices for profitability or market share. This manufacturing ERP costing module is designed to help you accomplish this, regardless of the size of your operation.

Life Cycle Costing

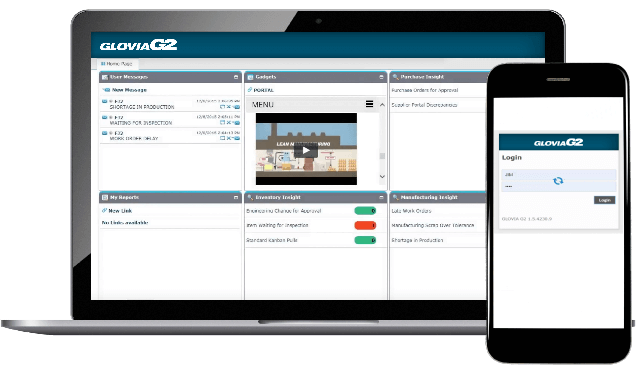

GLOVIA G2’s Costing module meets the needs of businesses whose products and services are supplied through both internal resources and from outside suppliers. Seven cost types can be used to create, model, and track costs throughout a product or service’s life cycle. The Costing module allows you to create simulated cost models for evaluation and analysis without affecting current operations or book values.

Elemental Costing

By accurately recognizing the true components of cost, the GLOVIA G2 elemental costing capabilities provide the critical visibility needed for effective cost control. Each item’s cost can be broken down into up to 24 cost elements that include material, material overheads, machine set-up and run time, labor set-up and run-time, fixed and variable labor/machine overheads, outside processing, shrink/yield/scrap, and freight. Additionally there are multiple user-defined cost elements. Additionally for each transaction conducted the financial posting for each specific cost element can be directed to a different financial account within the General Ledger.

Flexible Cost Roll-Ups

Cost roll-ups can be conducted using current or simulated data.

Cost roll-up capabilities are used as a planning tool for viewing projected costs and analyzing the impacts of changes to bills of materials, routings, and cost center rates. The system automatically saves the product structures and other source information used in the cost roll-up process. This provides data for a full cost roll-up analysis as well as back-up records for a complete audit trail, detailing any accounting impact.

Exception reports identify missing costs and any incomplete data that may lead to incorrect costing results (i.e. missing routings, BOM’s, Labor rates, etc.).

Cost roll-over capabilities provide a full comparative and valuation analysis so that the impact of the roll-over can be fully assessed before the roll-over. The ability to roll-back to the previous standard provides a safety net in the unlikely event that a roll-over be viewed as unacceptable and needs to be reversed.

Operational Cost Visibility

The item cost records in GLOVIA G2’s Costing ERP module are structured to show a hierarchical view of the costs for each item’s subassemblies, components and tasks. At each level of the item, the relationship of the materials used may be associated with the value-added costs of manufacturing or service delivery. This provides the means to value an item or service accurately as it progresses through the sequence of operations.

Three Costing Methods

- Standard

- Actual

- Average

Seven Item Cost Types Including:

- Standard

- Current

- Previous standard

- Next standard

- Simulated

Item Cost Elements

- Material and material overhead

- Machine run-time, setup, fixed and variable overhead

- Labor run-time, setup, fixed and variable overhead

- Outside processing

- Freight

- User-defined cost elements

- Shrink / scrap

- Indirect costs

- ‘Memo’ cost elements that can be excluded from cost roll-up

Multi-level Product Structure and Operation Level Cost Visibility

- Multi-level product costing visibility

- Value added costs can be identified to the specific operation they are incurred on.

- Components costs can also identified to the specific operation they will be consumed on.

Cost Roll-Up and Cost Roll-Over Processing

- Roll up costs by product and cost type,

- Simulate next year’s standard based on latest or planned production routings, item revisions, latest purchase prices, planned labor/machine rates, etc.

- Simulate impact on inventory valuation prior to setting new standard

- Provides the confidence to prepare, simulate, know and understand the exact impact of rolling over the new planned standard to standard.

Historical Item Cost Information

- Manufacturing and purchasing activity

- Detailed actuals from manufacturing and purchasing receipts

- Accumulated elemental costs

- Last item cost with elemental detail

- Last quantity completed or received

Download CrescentOne data sheet to learn more about implementing our GLOVIA G2 Costing ERP Module at your company.

DownloadExplore More Capabilities

Select a product category below to see how CrescentOne can improve a particular aspect of your business