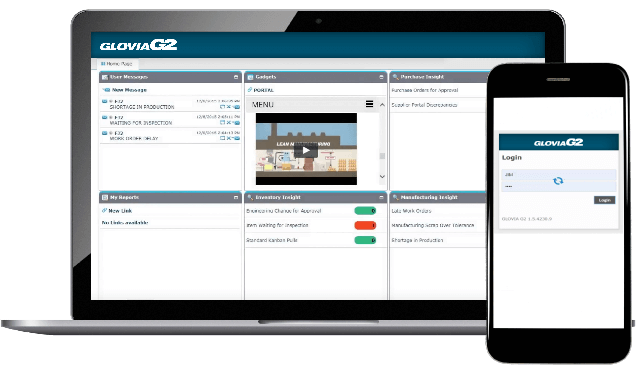

The foundation of good quality management and quality improvement processes is good quality related data. The GLOVIA G2 Quality Management software module provides tools that help collect and manage this data, to support quality initiatives throughout all areas of your business from product definition, through sales, and on to financial reporting.

Whatever quality management and process improvement programs your company chooses to implement, whether it’s Six Sigma, Total Quality Management (TQM), or process standardization required for ISO requirements; the GLOVIA G2 Quality Management software module can provide the information you need.

GLOVIA G2 provides robust Quality Management practices in all ERP functional areas:

- Engineering

- Costing

- Procurement

- Inventory Management

- Manufacturing Management

- Planning

- Sales

- Accounting

- Aftermarket Service

Defined at the Component or Assembly level

This quality management software module can define quality metrics whether manufacturing or buying components and finished products at the component or assembly level:

- Vendor certificationInspection criteria for purchase material at an Item level:

- Quality metric definition

- Ability to define quality and inspection procedures

- Definition of acceptable or defective material whether on a unit by unit or on a parts per million (PPM) basis

- Ability to define problem resolution statuses and disposition defective material for rework, return to vendor, use-as-is, or scrap

- Ability to segregate; rework; or return defective material at any time

- Automatically generate action or resolution requests and distribute to both internal users and outside suppliers via e-mail and exception notice

- Maintain quality data on an item by item and supplier by supplier basis for historical performance analysis

- Maintain supplier performance ratings in support of scorecarding

Work-in-Process (WIP)

GLOVIA G2’s Work-in-Process (WIP) Quality Management and Line-Side Inspection provides the capability to:

- Define inspection operations with acceptance criteria enabling automatic application to inspection results

- Apply visual insight to the line-side inspection activities that need to be conducted during production operational steps. This visibility allows both the line-side inspection activities and inspection resources to be pro-actively scheduled and managed, thus minimizing bottleneck inefficiencies and reducing WIP and line-side inventory

- Get instant access to specific quality process instructions and electronic copies of the relevant quality procedures and inspection documents, including rework operations and processes

- Capability to define control plans for both manufacturing in-process and incoming inspection processes

- Scrap in-process assemblies or components and accurately reflect the cost of this scrap

- Reflect rework costs as actuals or variances against manufacturing standardsSegregate non-conformant material or assemblies for later analysisRecord inspection results notesAccess detailed quality results and provide the information necessary to present a visual analytical understanding of quality and how it can be improved

- Execute failure alerts – immediately escalate critical issues to the relevant personnel

Integration

Of course, GLOVIA G2 provides complete integration between Quality Management Software and Financial Reporting ERP module:

- Automatically generate credit memos for defective purchased materials

- Process returns to vendors (RTV’s)

- Process customer returns

- Record and post all quality related costs to the general ledger

Download CrescentOne for more information about the GLOVIA G2 Quality Management ERP Module for manufacturing.

DownloadExplore More Capabilities

Select a product category below to see how CrescentOne can improve a particular aspect of your business